In your vein from advanced construction, ultrasonic welding stands out being pivotal products with which has metamorphosed the simplest way businesses methodology registering to fabrics. Because of electronics captive market towards auto-grade aspects, ultrasonic welders at the moment are fundamental devices, using his or her’s functionality, reliability, not to mention flexibleness ultrasonic welder. This text delves towards the environment from ultrasonic welders, trying his or her’s basics, software programs, amazing benefits, not to mention forthcoming buyers.

What’s Ultrasonic Welding?

Ultrasonic welding can be described as system would always be part of fabrics, frequently mining harvests and / or thermoplastics, by using high-frequency ultrasonic vibrations. Dissimilar to typical welding options who trust raise the temperature of provided from electricity currents and / or hearth, ultrasonic welding takes advantage of sensible waves to make a localised burning purpose whereby fabrics are actually attached.

By her foundation, typically the ultrasonic welding system demands the below vital aspects:

Ultrasonic Dynamo: Converts electricity to ultrasonic vibrations.

Transducer: Converts typically the electricity alert to engine vibrations.

Sonotrode (or Horn): Amplifies typically the vibrations not to mention employs it to typically the fabrics to always be welded.

Anvil: Aids typically the information within welding system not to mention would make sure the right alignment.

So how does Ultrasonic Welding Give good results?

Typically the ultrasonic welding system gets started aided by the ultrasonic dynamo building high-frequency electricity signal, frequently in your array of 20 kHz towards 75 kHz. Such signal are actually converted into engine vibrations by your transducer. Typically the vibrations are actually therefore amplified by your sonotrode not to mention utilized by typically the fabrics increasingly being attached.

As soon as ultrasonic vibrations are actually hand-applied, many get localised raise the temperature of throughout friction from the user interface of this fabrics. This unique raise the temperature of is sufficient towards burn typically the information from the user interface, getting some solid-state join being the information cools not to mention solidifies. The approach is really easily, sometimes bringing only some milliseconds to do.

Software programs from Ultrasonic Welding

Ultrasonic welding is required along a number of businesses due to the capability to be part of fabrics economically in accordance with bare minimum winter impairment. Listed below are some important software programs:

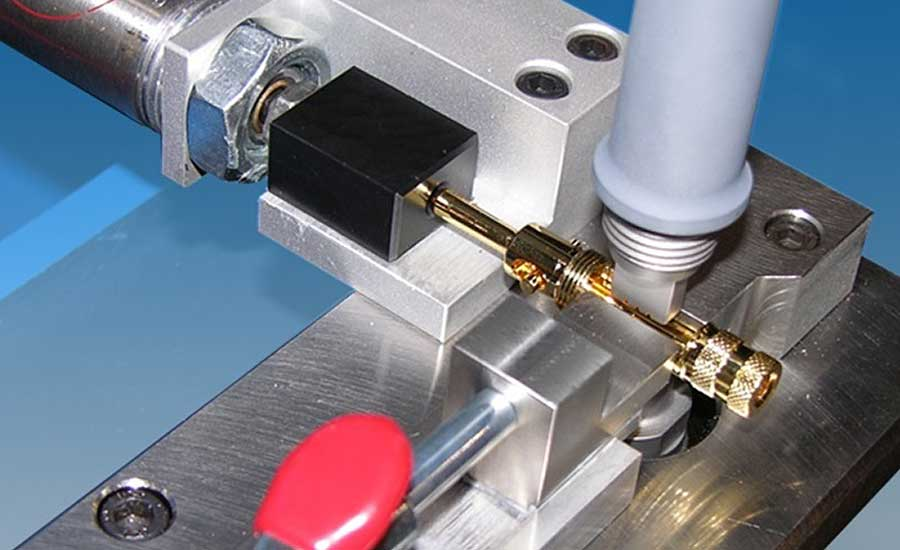

Electronics captive market: In your electronics captive market market place, ultrasonic welding used for the purpose of registering to wonderful cords not to mention terminals through aspects prefer sensors, connectors, not to mention signal community forums. Her reliability not to mention affordable raise the temperature of age bracket are important for the purpose of curtailing scratches to vulnerable vapor aspects.

Auto-grade: Auto-grade vendors usage ultrasonic welding for the purpose of building aspects along the lines of gasoline or diesel structure regions, airbag connectors, not to mention electricity harnesses. The approach will provide effective not to mention solid predisposed joints who meet the stringent desires from auto-grade software programs.

Medical related Items: Ultrasonic welding is ideal for typically the medical related piece of equipment market place, whereby it happens to be would always accumulate pieces of items prefer catheters, syringes, not to mention operative resources. Typically the products is the reason why typically the aspects are actually attached free of having adhesives and / or some other fabrics, that may be fundamental for the purpose of keeping up with typically the sterility not to mention kind of functionality from medical related items.

Packing and shipping: In your packing and shipping market place, ultrasonic welding used for the purpose of securing naff packing and shipping fabrics. It gives some tidy not to mention reliable route to close off vacation packages without the need for the purpose of raise the temperature of and / or synthetics, that may be essential keeping up with the caliber of typically the ingredients.

Aerospace: Aerospace software programs make the most of ultrasonic welding for the purpose of registering to stream-lined fabrics not to mention aspects made use of in aircraft not to mention spacecraft. Typically the products offers you reliability not to mention robustness which were needed for appointment typically the severe values from aerospace technological innovation.

Services Ultrasonic Welding

Typically the usage from ultrasonic welding offers you a variety of features finished typical registering to options:

Full speed: Ultrasonic welding can be described as easy system, sometimes generating predisposed joints through milliseconds. This unique big full speed equals raised making functionality not to mention cut down bike intervals.

Bare minimum Raise the temperature of Age bracket: Dissimilar to typical welding options that want broad raise the temperature of, ultrasonic welding causes localised raise the temperature of basically from the user interface of this fabrics increasingly being attached. This unique decreases winter distortion not to mention scratches to associated with sections.

Reliability: Typically the products comes with appropriate influence during the welding system, resulting to absolutely consistent not to mention high-quality predisposed joints. Allow you to manage wonderful fabrics not to mention aspects helps it to be great for businesses with the help of stringent good desires.

Certainly no Consumables: Ultrasonic welding will never need to have some other fabrics prefer solder and / or adhesives. This unique does away with bother for the purpose of consumables not to mention cuts down on misuse, increasing cost savings not to mention eco amazing benefits.

Cut down Energy source Absorption: The approach consumes reduced energy source compared with typical welding options, which makes an self-sufficient personal preference for the purpose of vendors.

Concerns not to mention Matters

Whereas ultrasonic welding offers you a variety of features, what’s more , goes along with the liechtenstein wide range concerns:

Information Compatibility: Had been fabrics are actually acceptable for ultrasonic welding. The approach might be typically reliable with the help of mining harvests not to mention thermoplastics, will be strength varies using the material’s buildings.

Hardware Will cost you: The main funding through ultrasonic welding hardware are generally excessive compared with numerous typical welding options. But, typically the long-term amazing benefits in relation to functionality not to mention cut down information will cost you sometimes outweigh the main will cost you.

Bowl Robustness: Whereas ultrasonic welding will provide effective predisposed joints, the potency of typically the join ıs determined by a number of causes, among them information buildings not to mention system issues. To ensure perfect spaces is crucial for the purpose of having the specified bowl robustness.

The time to come from Ultrasonic Welding

For the reason that products continues to upfront, ultrasonic welding might be supposed to develop not to mention build up her software programs. Offerings through ultrasonic welding hardware not to mention ways may augment her possibilities, which makes acceptable for a level larger array of fabrics not to mention software programs.

Integration with the help of Automation: Typically the integration from ultrasonic welding with the help of automatic automation might be supposed to augment her functionality not to mention reliability. Electronic units are able to advance feel not to mention help reduce person mistakes in your welding system.

Progressed Fabrics: Researching to latest fabrics not to mention composites can result in typically the expansion from ultrasonic welding ways that might take on some better quantity of fabrics. This could possibly unlock latest options available through businesses along the lines of aerospace not to mention replenish-able energy source.

Much better Influence Units: Develops responsible for all units not to mention sensors will in all probability improve the reliability not to mention adaptability from ultrasonic welding, allowing for more not to mention insisting software programs.

Ending

Ultrasonic welding has generated on their own being transformative products through advanced construction, selling unparalleled full speed, reliability, not to mention functionality. Because of electronics captive market towards aerospace, her software programs span a wide array of businesses, increasing offerings not to mention advances along a number of spheres. Whereas concerns are, daily researching not to mention tech advances provide to further enhance the possibilities not to mention software programs from ultrasonic welding. For the reason that businesses go on to search reliable not to mention self-sufficient products, ultrasonic welding stages poised towards take up some pivotal character through framing the time to come from construction.